The multi-station cold forging machine, in terms of working principle, achieves the forging and forming of metal wire through continuous multi-stations.

It does not require heating and gradually shapes through molds at room temperature.

Process flow:

Feeding and cutting : Metal wire is fed into the equipment through the feeding mechanism. After being fed by the roller or the straight bar, it is cut into

smaller to the set length by the cutting mechanism.

Upsetting and forming : The billet enters each station in sequence and is shaped through processes such as pressing the ball, pressing the Angle, punching,

threading, and reducing the diameter , ultimately forming the required shape.

Multi-station : By arranging 1 to 7 stations horizontally or vertically, continuous production is achieved, with an efficiency increase of 25% to 30% compared

to traditional single-station equipment.

Key technical features:

High material utilization rate : By adopting a modular mold system (such as die housing, die core, and die core), the material utilization rate can reach 80%-90%.

Precision control : Through the buffer spring device and the block mold core design, the tolerance can be controlled within ±0.005mm, and the surface finish can reach

V5 or above.

Scope of application:

It is suitable for the production of standard parts such as bolts, nuts and rivets, as well as special-shaped parts, and supports various materials including copper,

aluminum and steel.

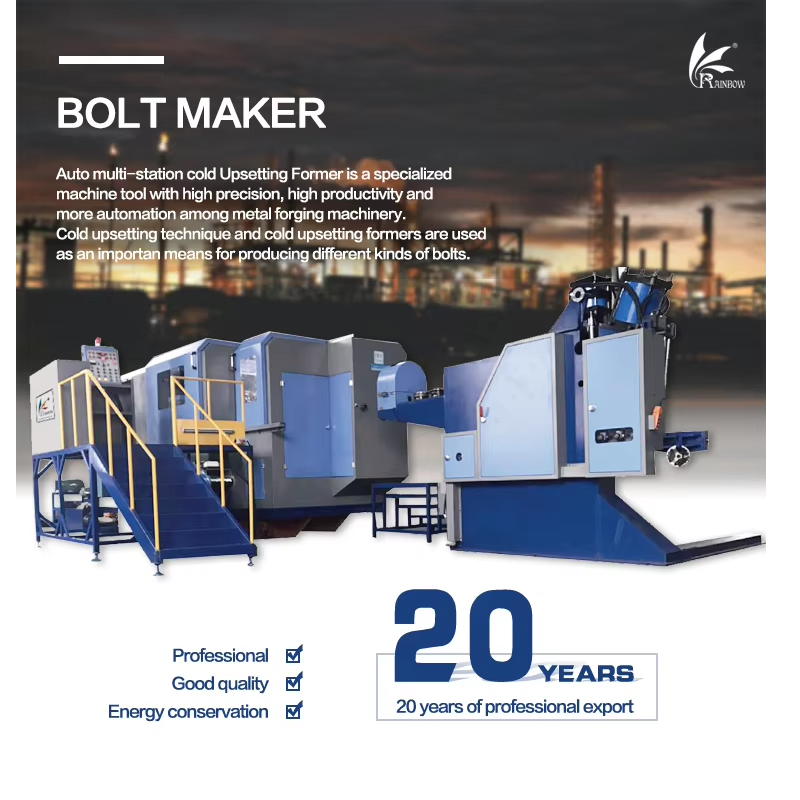

The multi-station automatic cold forging machine is a highly efficient and automated forging and pressing machine, mainly used for manufacturing standard parts

such as bolts, nuts and rivets, as well as special-shaped parts. It adopts a variety of materials such as copper, aluminum, carbon steel, alloy steel,

stainless steel and titanium alloy, with a material utilization rate of up to 80%-90%. Through continuous multi-station production, processes such as cutting,

heading, accumulation, forming, chamfering, thread rolling, diameter reduction and edge cutting are completed in an integrated manner. This equipment is widely

used in fields such as aviation, automobiles, and mechanical manufacturing. It features technical characteristics such as air pressure clutches, pneumatic clamp

mechanisms, and PLC numerical control systems, ensuring processing accuracy and production stability

Technical features:

1. Automation control: Equipped with imported frequency converters and PLC numerical control detection devices,

it supports stepless speed regulation of production speed and automatic fault alarm.

2. Stable clamping: The rotary pendulum pneumatic clamping mechanism can adjust the clamping force, maintaining stability even during high-speed operation.

3. Wear-resistant design: The main and auxiliary sliders are made of wear-resistant materials, and the inner side of the machine body is made of imported alloy steel that has undergone quenching treatment.

4. Safety protection: Equipped with pressure detection and safe shutdown functions to prevent overload or mold damage

Application field:

This equipment is a key production device in the standard parts industry, and the parts it manufactures are widely used in:

Transportation: Aviation fasteners, automotive bolts, rail transit accessories;

Mechanical manufacturing: Industrial equipment connectors, sewing machine parts;

Civilian sector: building hardware, furniture screws, daily consumer goods

Typical model parameters:

RBF-64S: 4 stations, maximum cutoff diameter 8mm, production speed 140-240pcs/min ;

RBF-84S: 4 stations, maximum cutoff diameter 10mm, production speed 120-200pcs/min ;

RBF-104S:4 workstations, maximum cutoff diameter 120mm, main motor power 30Kw

Company address:No. 1560-2 chuangxin 2nd road, songbei district, Harbin.

Mailbox:chen@rainbowtechnology.net

No. 1560-2, 2nd chuangxin road, songbei district, Harbin.

+86-451-51066797

WhatsApp/Mobile : +86-18604505477